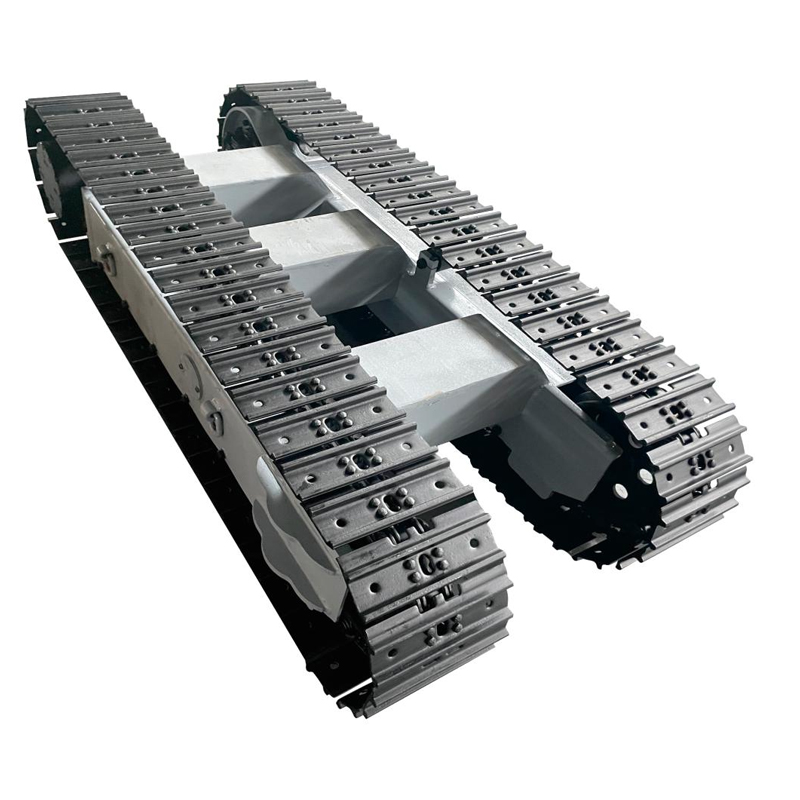

Customized 0.5TON- 20 TON Steel or Rubber Crawler Track Undercarriage System# Steel Tracks# Rubber Tracks Undercarriage

Product Description

In order to recommend a suitable drawing and quotation to you,we need to know:

1. Steel or rubber track undercarriage

2. Loading capacity of the track undercarriage(the weight of the whole machine excluding of track undercarriage)

3. Length

4. Width

5. Height

6. Travel speed

7. Climbing capacity

8. Working flow rate(each side of track undercarriage)

9. Working pressure

10. Order quantity

11. Port of destination

Our factory are specially focused in steel and rubber tracked undercarriage production. For Steel Track Undercarriage we produce the range from 0.5ton to 20tons, we can customize as customers' request. Different functions like with slewing bearing, telescopic, remote control are avalaible. We have sold our undercarriage to Asian, European. AUS, South American etc markets.

Features

1) Integrated two-speed or compact plunger hydraulic motor and reducer are adopted, and the driver features small volume, large traction, low energy consumption and so on; and the running motor and pipelines can be buried in a crawler to prevent damage caused by rough roads. A parking brake and a balance valve are arranged in the running motor to ensure stable running and stopping and reliable braking.

2) An all-welded heavy-load running frame is adopted, and crawler frames on two sides are rigidly welded with an intermediate beam.

3) The track roller, carrier roller and idler are sealed by floating oil to ensure that no need extra lubricating oil during long-term work.

4) A standard grease tensioning cylinder and a spring with a shock absorber adjust the undercarriage better.

5) Lubricating grease lubricates a crawler sealing piece, so the insides of crawler chain link pins and pin bushes are more wear-resistant; and a crawler link adopts a ram-type production mode, so the joint of the crawler is firmer and more durable. A crawler link adopts a ram-type production mode, so the joint of the crawler is firmer and more durable.

6) Track shoes made of high-strength alloy steel can bear external impact when the machine walks on rough or wet ground.

We are one professional manufacturer in construction machinery industry,not only can offer series of undercarriage spare parts,but also can offer steel and rubber track undercarriage crawler track chassis for drilling rig, crawler conveyor,crusher,crawler paver etc crawler type equipment.

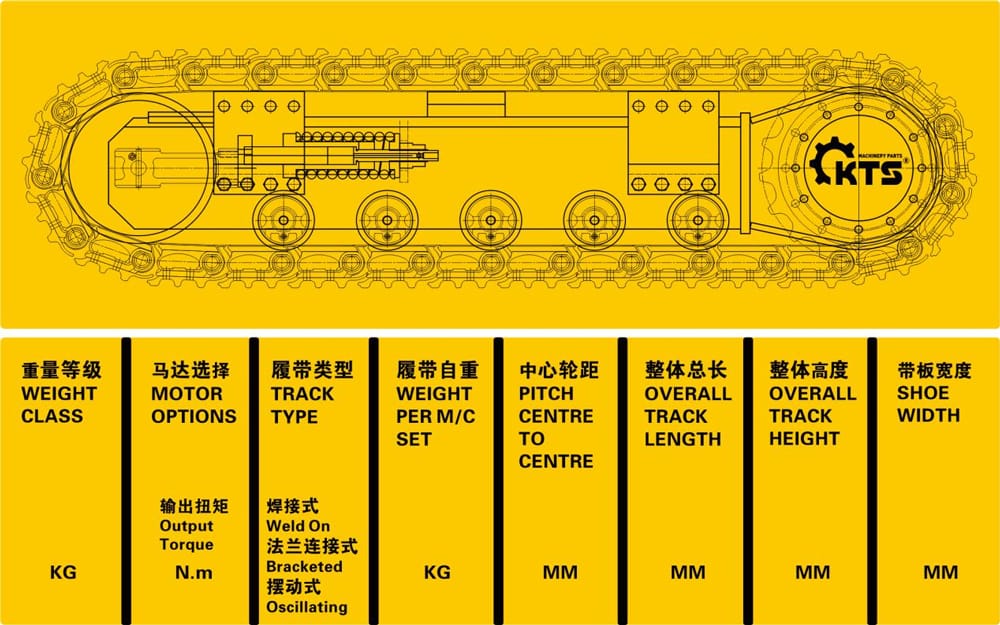

Track Types

1. Weld on

2. Bracketed

3. Oscillating

FAQ

1. Q: Are you a trader or manufacturer?

A: We are the manufacturer in China.

2. Q: Can you supply customize service?

A: Yes, we can customize the undercarriage according to your demand.

3. Q: How is your products?

A: We have professional engineers and experienced team, and with many years experience in this field, our product are widly welcomed by many customers.

4. Q: How is your price?

A: Our price is based on the quality, we give the competitive price to every customer! Here you can own Europe quality on Chinese price!

5. Q: How is your after-sale service?

A: We can give you one years after sales warranty, and any quality problem caused by manufacturing defects can be unconditionally interchanged into a new one.

6. Q: How to place order?

A: 1 set